Products & industries > Printing machine bags

Printing machine bags

At BRANOfilter we understand that high-quality printing results can only be achieved with high-quality filter products printing process is possible. That’s why we offer relatives filter bag and mats for them Circulation systems from offset and Rotary printing machines that can be seamlessly integrated into your production processes. The use of state-of-the-art materials and technology allows for efficient removal of paint flakes, dust and other contaminants, maintaining water and paint balance and minimizing wear and tear on your machines.

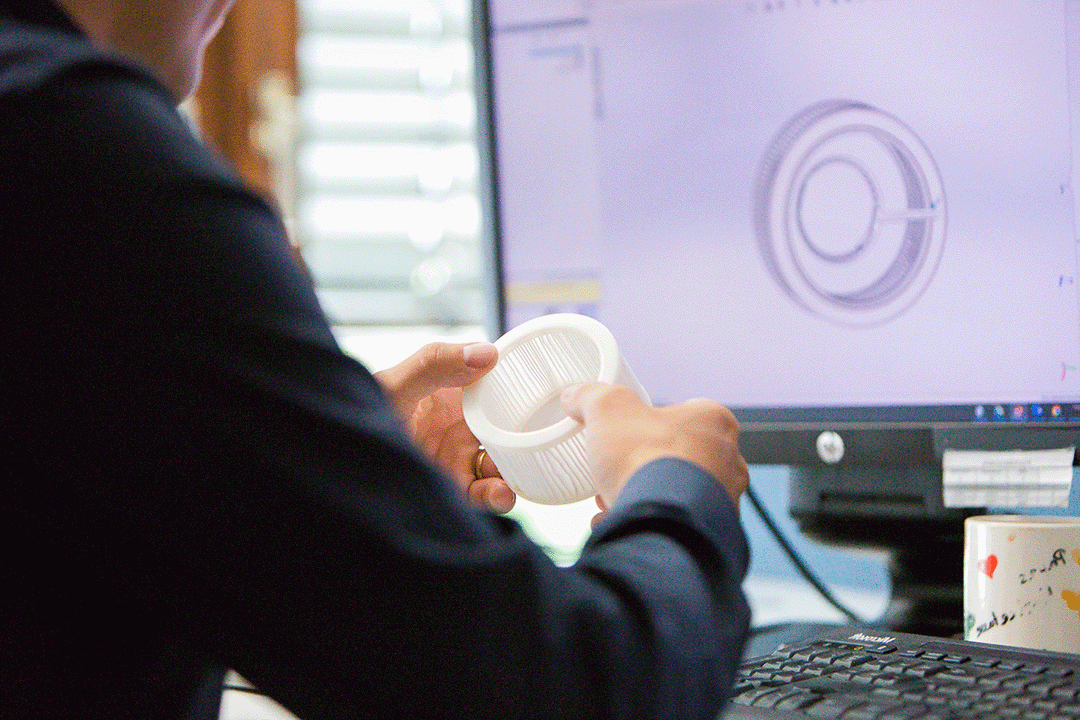

Our filter systems find their optimal application in pressurized water treatment systems and circulation systems, especially in so-called Fountain solution devices. By using high-quality filter material, you not only achieve first-class filter results, but also sustainably improve the quality of your printed products. Equipped with a practical plastic handle and fastening ring, ours are impressive Pressurized water filter bags not only through high filter performance and stability, but also through fair prices. We design our printing machine bags with a clear focus on one thing easy maintenanceto minimize downtime and ensure smooth production.

Optimize your printing results and prevent costly repairs by changing filters in your printing machines and lines at regular intervals. At BRANOfilter we support you high-quality filter systems and a dedicated team to meet your specific needs and increase the efficiency of your printing processes.

Areas of application

The printing machine bags are used in large printing machines for the production of gravure, rotary and offset printing articles. They are used in the dampening water treatment of pressurized water treatment systems from manufacturers such as HEIDELBERG, KBA, Komori, manroland and all systems with Technotrans systems.

Printing & Varnishing

Printing & Varnishing Features

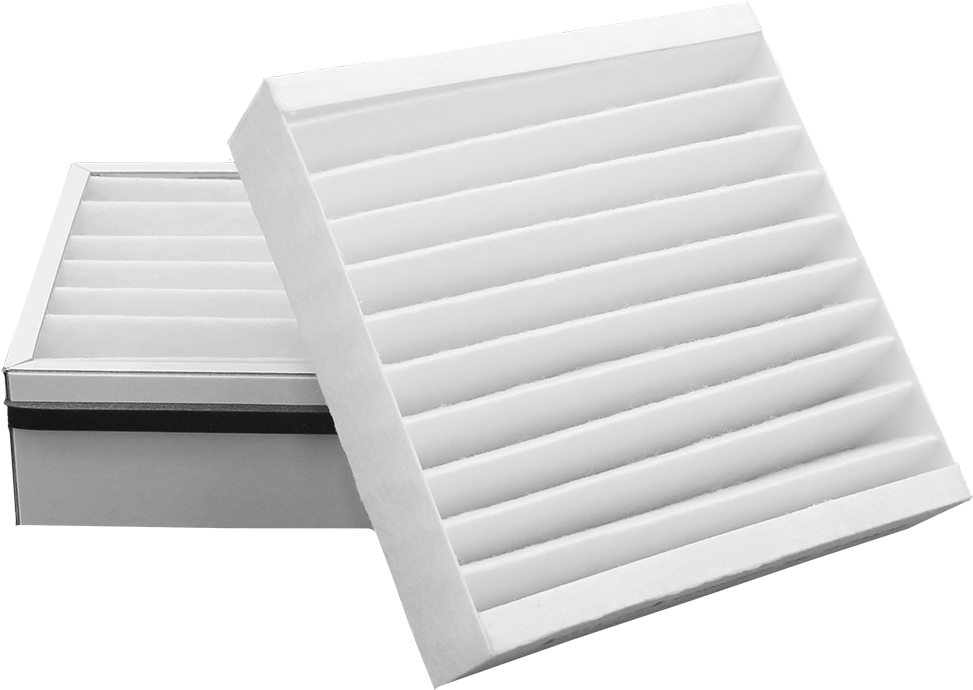

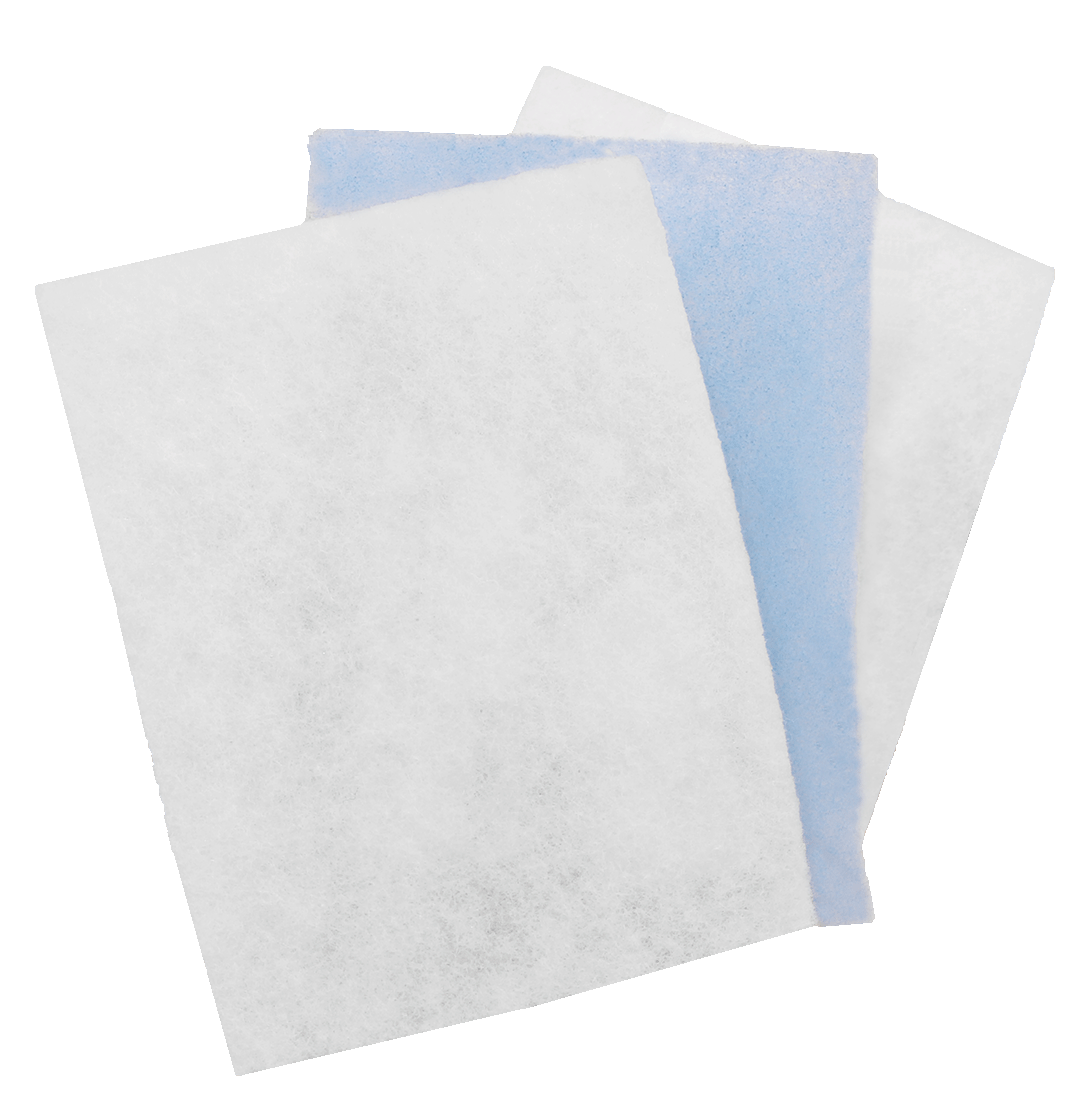

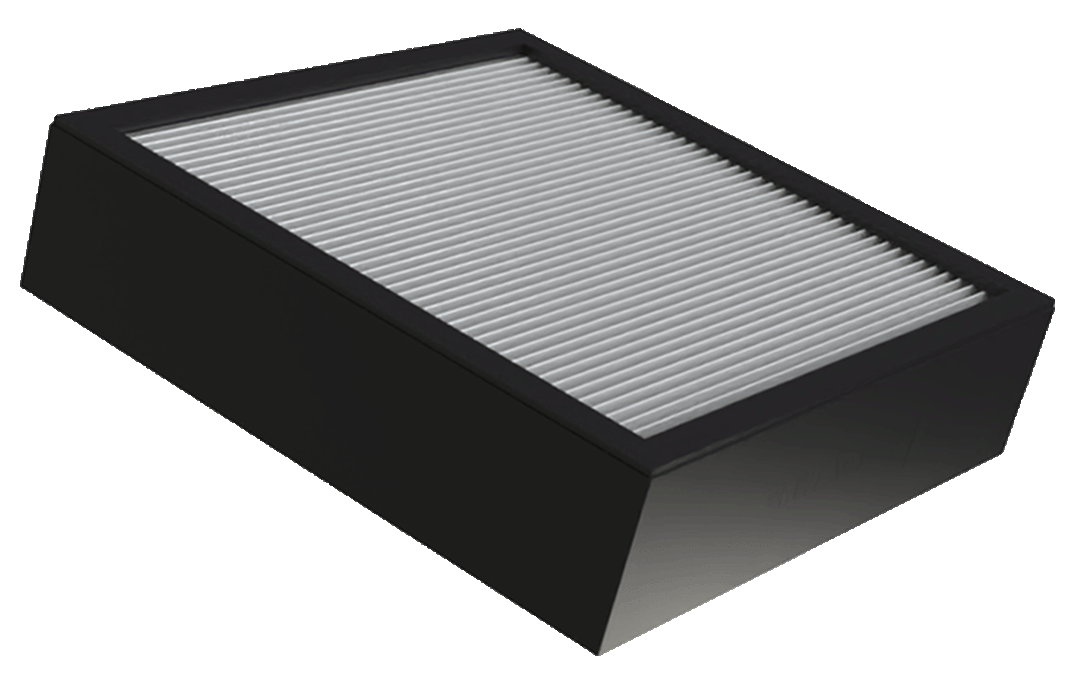

- Single-layer or multi-layer PP filter fleece

- Practical plastic handle and fastening ring

- Filter class G3/G4/M5

- Individually adapted

- Surface mass DIN EN 536, 250-350 g/m²

- Thickness according to DIN EN 534, approx. 1-2 mm

Technical data

This might also interest you

Matching products

Contact

BRANOfilter GmbH

Industriestraße 23

90599 Dietenhofen

Germany

Phone: +49 9824 955 0

Email: info@branofilter.de

Industries

Household

Professional cleaning

HVAC

Healthcare & Dentistry

Cosmetic treatment

Material processing

Printing & Varnishing

Working with hazardous substances

Products

Filter bags for household vacuum cleaners

Filter bags for industrial vacuum cleaners

Filter bag for dental suction

HEPA filter

Panel filter

Compact filter

Motor protection filter

Filter bags for manicure and pedicure

Safety and disposal bag

Filter bags for chip extraction

Cartridge and cassette filters

Pocket filters

Printing machine bags

Filter mats

Exhaust and supply air filters

Z line filter

Disposable mop

Menu

Service

© Copyright 2025. BRANOfilter GmbH. All rights reserved.